Before & After Photo Gallery

In this gallery, we showcase a series of before and after photos that demonstrate the remarkable results achieved through the use of our specialty blasting soda with our industry leading soda blasting machine.

Surface coatings, such as paint, rust, grease, and grime, can be stubborn and difficult to remove. Traditional methods like sandblasting often result in damage to the underlying surface, making it unsuitable for delicate materials or intricate designs. However, soda blasting offers a gentle yet effective solution.

Our patented self-cleaning venturi technology, featured in our popular BB100 soda blasters, ensures a precise and even flow of the blasting medium. This technology not only enhances the efficiency of the process but also reduces the consumption of soda by an impressive 20% compared to modified sand blasters.

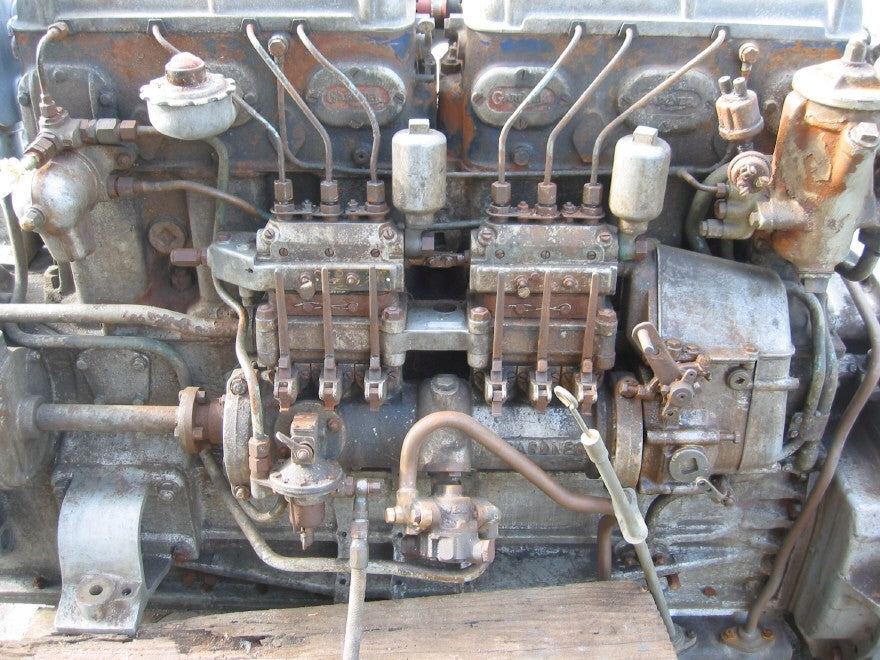

Diesel Engine

Our equipment and soda is tough enough to remove years of scaling, grease, and weathering. Also, its properties mean its gentle enough to not warp or damage the intricate parts of the engine.

Before Soda Blasting

After Soda Blasting

Mold Remediation

Mold is notoriously difficult to remove fully. Soda blasting has the unique properties necessary to permanently remove mold while also removing the odor.

Before Soda Blasting

After Soda Blasting

Steel Auto Body

Removing paint, primer, body filler is a common step in restoring automobiles. Unlike other blasting methods, soda blasting is tough enough to remove it all without leaving any trace to the underlying sheet metal.

Before Soda Blasting

After Soda Blasting

Brick Fire / Smoke Damage

Masonry can be brought back to its original look after even the most serious damage from fire and smoke.

Before Soda Blasting

After Soda Blasting

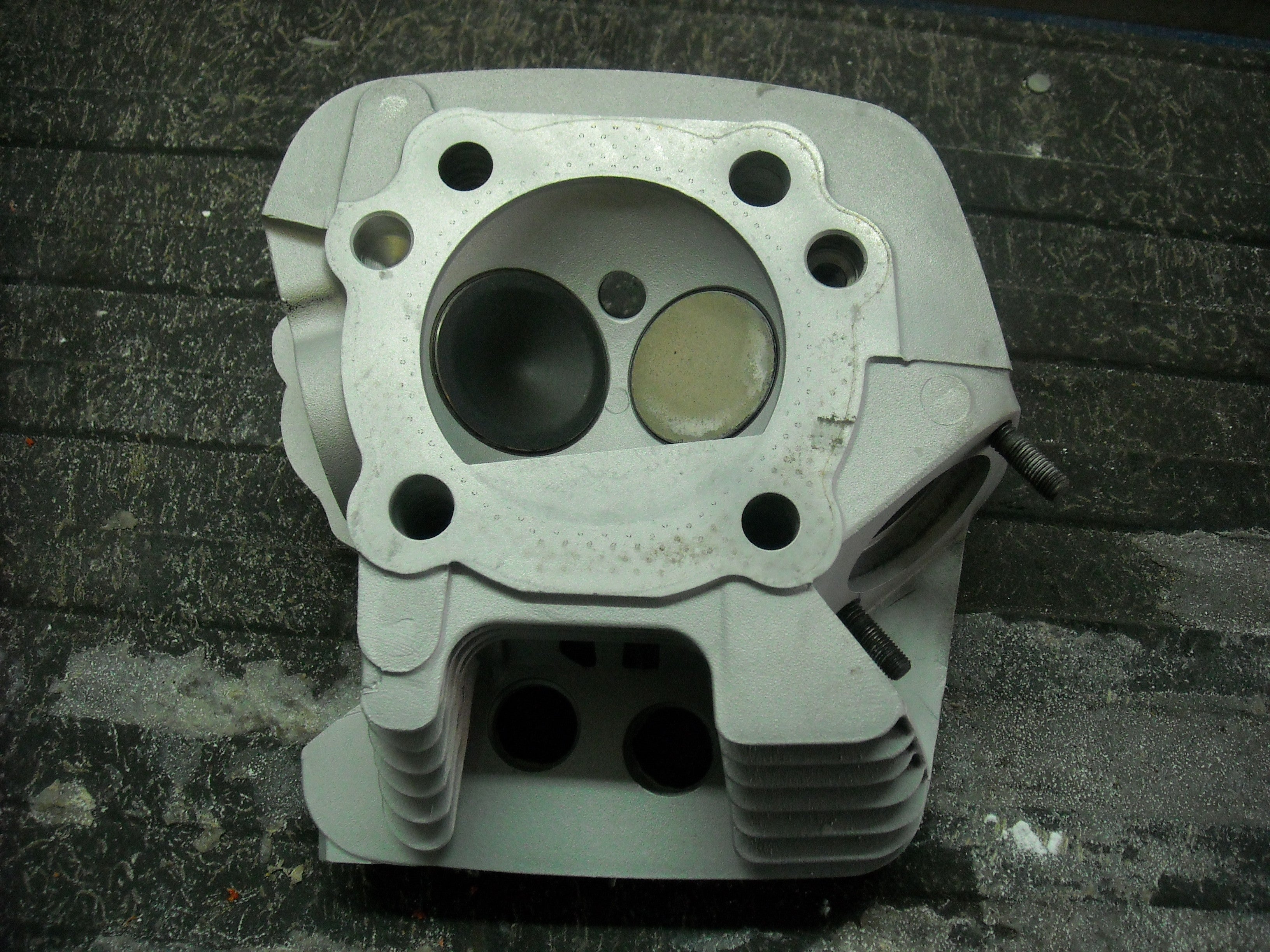

Powersports Parts

It is possible to clean parts so they look almost new again. In fact, many "refurbished" parts you may find for sale are simply soda blasted components that looked undesirable before a few minutes with Soda Works style equipment.

Before Soda Blasting

Before Soda Blasting

Wood Smoke / Fire Damage

Using specialty soda blasting equipment serves a dual purpose in fire and smoke remediation. It cleans the fire and smoke residue as you would expect, but soda's unique properties also means that it captures and removes the odor as well. This odor capture aspect is one of the key advantages versus other cleaning methods.

Before Soda Blasting

After Soda Blasting

Fiberglass Auto Body

Soda will not damage fiberglass either! Easily remove paint, primer and filler from the surface of any fiberglass component.

Before Soda Blasting

After Soda Blasting

Industrial Cleaning

Tar overflow created quite a mess. Blasting with soda removed all tar, paint, and discoloration so this tanker can be repainted and put back into service.

Before Soda Blasting

After Soda Blasting

Concrete Smoke / Fire Damage

Concrete can be cleaned to like new again. In this case the odor is removed as well.

Before Soda Blasting

After Soda Blasting

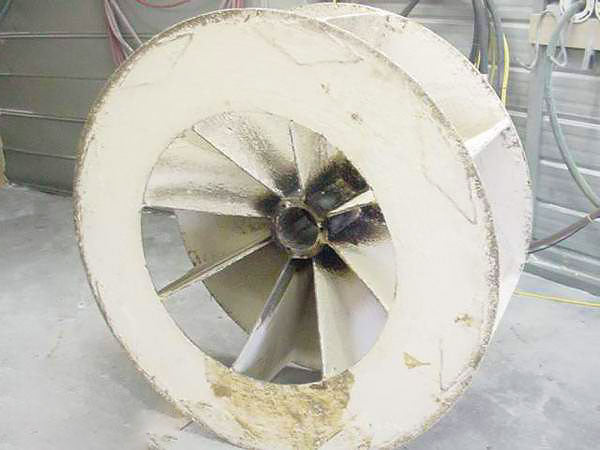

Steel Industrial Components

Breathe new life into aging equipment, components, and parts.

Before Soda Blasting

After Soda Blasting

Trailer Paint Removal

This trailer needed all paint, decals, and non-substrate coatings removed to be prepared for the proper adhesion for a trailer wrap. Soda blasting ensures a clean smooth surface free from warping or etching. The ideal method for prepping trailers, cars, and trucks with aging paint for wrapping.

Before Soda Blasting

After Soda Blasting

Wood Paneling

Removing sealant, varnish, and coatings from finsihed wood can be tedious, but not after a pass with our soda blaster.

Before Soda Blasting

After Soda Blasting

Carbon Fiber

Before Soda Blasting

After Soda Blasting

Aluminum Body

Before Soda Blasting

After Soda Blasting

Wood Exterior

Log cabins, cedar siding, pine, you name it. Our equipment and soda can make it look like the day it was built.

Before Soda Blasting

After Soda Blasting

Industrial Cleaning

Storage silo with heavy overspill. Thin aluminum shell means you need heavy coating removal power without warping or damaging the substrate. Soda is usually the best choice in these scenarios.

Before Soda Blasting

After Soda Blasting

As you can see from these images, soda blasting effectively removes surface coatings, revealing the true beauty and integrity of the underlying material. Whether it's restoring a vintage car, revitalizing a historic building, or simply rejuvenating a worn-out surface, soda blasting delivers exceptional results.

But what makes soda blasting so unique? The secret lies in the blasting medium itself. Soda blasting utilizes sodium bicarbonate, commonly known as baking soda, as the primary abrasive. This gentle yet highly effective substance is non-toxic, non-hazardous, and environmentally friendly. It can be safely used on a wide range of materials, including metal, wood, fiberglass, and even delicate surfaces like glass and chrome.

Furthermore, soda blasting eliminates the need for harsh chemicals or solvents, making it a safer and more sustainable option. It effectively removes surface coatings without causing damage or leaving behind residue, ensuring a clean and pristine finish.