Blasting Soda

When it comes to blasting away coatings, stains, grime, gunk, and grease, you need the right stuff for the job. And that's where Soda Works Natrium blasting media steps in. This stuff isn't your run-of-the-mill baking soda; it's the heavy-duty, purpose-formulated sizing and consistency, no filler additives, pure Sodium Bicarbonate made specifically for soda blasting.

What Makes Our Natrium Soda-Blasting Media Stand Out?

- Select A Size: Choose a granule size that suits your use. Natrium 260 is the most appropriate for most of our customers. But, whichever you choose it will be consistently sized to specification and pure blasting soda to minimize dust and maximize production.

- Eco-Friendly: Our blasting soda is food-grade. This means it's pure baking soda. It can be used in cleaning applications for food preparation, food processing, and any other application where contamination or harsh chemicals would be detrimental. Also, it can be washed away fully with water and is safe for wastewater systems.

- Minimize Dust: With larger consistent particle sizes and no additives, the dust created from our soda is significantly less.

- Consistent Size: Consistent sizing of the blasting soda particle ensures a smooth flow, faster blasting, and better visibility. Get more done with less.

- Surface-Safe: No risk to the substrates you blast. Our blasting soda is gentle, effective, and safe for use on glass, chrome, rubber, bearings, and more. It won't etch, pit, or harm the surface.

- Made in the USA: In a world where almost everything is from overseas, our baking soda for soda blasting is made in the USA. Quality you can trust and in doing so you support local manufacturing.

- Cost Savings: A larger consistent size of soda particles, with no impurities, means you will be more productive with your blasting. This means you use less soda and finish projects faster. Either it is money saved or more earned, whichever way you want to look at it.

So, if you're ready to take your soda blasting to the next level, look no further than Soda Works Blasting Media. With its maximum productivity, eco-friendly formula, dust-free efficiency, and surface-safe cleaning power, it's the ultimate solution for all your blasting needs.

We offer three grades of our specially formulated soda blast media

They vary based only on the average particle size or granulation.

Below we summarize the simple characteristics that define each grade of soda media and the applications they are generally useful for. Our recommendation is generally going to be the Natrium 260 for most applications. If you have questions regarding your specific use, our team is available to help you find the best grade for your project.

- Natrium 150

-

- 100 Mesh / 150 Average Micron

- Consistent Crystal Size / No Additives

- Ideal for removal of coatings on delicate surfaces such as decorative wood, thin deteriorating metal and other surface preparation where minimal substrate interaction is required.

-

Order Now

- Natrium 260

MOST POPULAR -

- 50 Mesh / 300 Average Micron

- Consistent Crystal Size / No Additives

- Best for most fire remediation, mold removal, automotive, aerospace, turbines, pumps, tanks, valves, and remanufacturing applications. Particularly effective on areas that require degreasing and coating removal as a single process or areas that need cleaning and odor control in a single process.

-

Order Now

- Natrium 300

-

- 45 Mesh / 350 Average Micron

- Consistent Crystal Size / No Additives

- Useful in some remanufacturing applications and for hard-to-remove coatings where other soda media may have been ineffective. Best for applications where the highest amount of productivity or minimal dust is needed.

-

Order Now

How Much Better is Our Blasting Soda?

Have a look at the video below to see the results in real time compared to the "other guys" brand you find in stores and at many distributors.

If you are not also using our specially designed soda blasting pot, then you are also burning even more soda and taking even more time on your soda blasting projects. Our purpose-built soda blasting equipment is up to 75% more efficient than a standard sandblasting pot.

The Soda Works BB100 blasting pot coupled with Natrium 260 is the most efficient and productive soda blasting setup available in the world!

This Soda Blasting Video is a side-by-side test comparing Soda Blasting Products: Natrium Products 260 Blasting Soda Media (LEFT) and the Other Guys Media (RIGHT). The test was under identical conditions. We used a Soda Works Buster Blaster Model 100 soda blast setup (The most productive and efficient on the market today). We completed the Natrium Products Soda video 1st and then cleaned out the blast pot refilled with Natural Brand Soda and completed the same amount of stripping. The test parameters and results are as follows:

- Blasting was performed at 125 psi using a #4 ( 1/4" I.D.) dry nozzle

- All pressure and media settings were exactly the same.

- The results below are based on identical coatings to be removed and size of blasted area.

The Natrium Products 260 Soda took 1 min. 38 seconds to complete.

The Other Brand Soda took 2 min. 45 seconds to complete the same amount of area.

As you can see, Natrium Products Soda Media is 36% more productive.

Natrium Products Blast Media was less dusty during the blast comparison, however, that is hard to determine in this video as the dust evacuation system is pulling approximately 20,000 cfm through the blast booth. This video was not set up to disparage another manufacturer's product. It demonstrates the benefits of using the Soda Works Buster blaster soda-blasting unit in conjunction with the Natrium Products brand soda-blasting media. When you combine the Soda Works Buster Blaster unit, with its patented metering system, and Natrium Products Blast Media, the highest quality blasting soda on the market, you get a combination of equipment and media that no other soda blasting system can match. More production with less media equals increased profit for you and more value for your soda blast customers.

Need A Sample?

We offer a sample program to help you see the difference. $10, a 5lb bag shipped to your door.

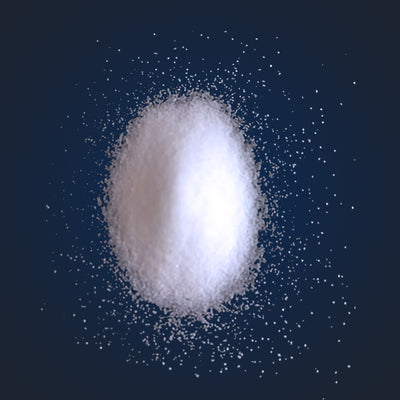

Natrium Up Close

Natrium Up Close

Natrium Soda Blasting Media is pure Sodium Bicarbonate. There are no "flow additives" or other adulterants which reduce efficiency and create additional dust.

Large & consistent crystal size means better production, less dust, faster projects, and impressive cost savings.

Our Recommendation for Blasting Soda

We have found the Natrium 260 to be the ideal size for soda blasting. Smaller crystals than the Natrium 260 don't get as much work done and larger crystals put excessive wear and tear on the equipment without resulting in significant gains in efficiency.

Owning our best-in-class soda blasting equipment is only part of the success equation. The results you obtain will vary with the type of soda blasting media, also known as sodium bicarbonate, bicarb, baking soda, or soda blasting powder, you choose to use. Not all baking soda makes good blasting soda. In fact, most baking soda will fail miserably at the task.

At Soda Works our goal is to provide you with the best soda blasting systems in the world. To reach this goal we have painstakingly analyzed every aspect of the soda blasting process. We have analyzed and perfected every aspect of our system down to the very baking soda that is being used in the process.

Why? It all has to do with particle size and in soda blasting, size matters. The size we are referring to is the size of the sodium bicarbonate crystal that makes up the media. We rely on soda blasting media that has a proprietary process for manufacturing consistently oversized crystals.

Whether you rely on our best-in-class equipment or not, our soda media is still the most productive and efficient sodium bicarbonate for soda blasting available.

Sort

Soda Works Blasting Media vs the Other Products

Make no mistake about it, Soda Works is the only company making a soda blaster that is designed from the ground up for professional soda blasting. All other equipment out there is "repurposed" equipment designed for sand or other abrasives which inherently inefficient for soda.

Other manufacturers tend to "blame the soda" and add "stuff" into the soda to allow it to flow properly though their equipment which diminishes the purity of the process in hopes of letting machines that are designed for sand or glass, to also be effective with soda.

Sodium bicarbonate is completely water-soluble. You can rinse every trace of it away with a hose. "Flow additives," typically calcium carbonate, are not water soluble. To remove them from your work site requires more time and effort on your part. What's more, the "flow additives" do not do any of the work of blasting; they simply make more dust and more mess for you to clean up afterward.

Natrium 260 Soda Blasting Media is the very best soda blasting media available. Believe us, we have tested them all. Our blasting soda is pure sodium bicarbonate so you have no additional environmental hoops to jump through. The manufacturing process gives a consistent, predictable product. With every shipment of Natrium 260 Soda Blasting Media we receive, there is an analysis report on that specific batch. We are happy to furnish this information to anyone.

We are also happy to send a free sample of our baking soda for soda blasting to anyone who want to see the difference up close. Just contact us to give us your shipping information, and we will get some into the mail to you right away. For orders, we can ship any amount from a single 50 lb. bag to multiple pallets.

When you use Natrium 260 soda blasting media with our soda blasting system you will be among the most productive and profitable soda blasters in the country!